Inner packaging printing technology can include silk screen priting, label paper, hot stamping, paint color, electroplating, and frosted. No matter how well-made your product is, there’s always a risk of being damaged during shipping. Inner packaging helps to cushion your product and prevent it from being damaged by bumps or drops.

If you’re selling a unique or high-end product, inner packaging can help it stand out from the competition. Luxury brands and skin care products are used inner packaging, which helps create an overall premium experience for customers.

This guide will provide a complete overview of the surface technics of inner packaging for skin care products.

What is the silk screen printing?

The cosmetic and skin-care industry has made great strides in developing new packaging technologies that can better protect delicate products from environmental damage. One such technology is silk screen printing, which is often used for inner packaging.

Silk screen printing is one of the most important surface technics for skin care products’ inner packaging. Silk screen printing offers several cosmetic and skin-care product benefits, including better light and oxygen exposure protection.

In addition to its good looks, silk screen printing is also very durable, and it can withstand a lot of wear and tear and won’t fade over time. This makes it an ideal choice for products that will be used frequently or stored for long periods of time.

Silk screen printing is an excellent option if you’re looking for a way to add some extra flair to your skin care product packaging. It’s affordable, looks great, and is built to last.

Feature

◇This new printing method uses a thin layer of silk to transfer ink onto the surface of the packaging.

◇It has a specific thickness and a strong three-dimensional sense.

◇Plate making is more convenient, the price is relatively cheap, and the operability is strong.

What is the label paper?

The label paper is very important for the surface technics of skin care products. It will determine the MOQ of skin care products. The label paper is a material used for skin care products’ inner packaging surface technics. This paper is made of cellulose and is coated with a thin layer of plastic.

The label paper is used to print information on the surface of the skin care product’s inner packaging. This material is also used to create a smooth and glossy finish on the skin care product’s inner packaging surface. The label paper is available in different thicknesses and weights.

The label paper’s weight and thickness will determine the printed information’s printing quality and durability. The label paper is a versatile material that can be used for a variety of surface technics. By understanding the label paper’s use, you can create a beautiful and professional finish on your skin care product’s inner packaging.

Feature

◇It is a very versatile technique used on different materials, including paper, cardboard, plastic, and metal.

◇Thanks to its superb accuracy and precision, it offers a wide range of design possibilities.

◇It is a very durable technic that can resist high temperatures and humidity levels.

What is the hot stamping?

Cosmetic and skin-care products are becoming increasingly popular as people become more concerned about their appearance. As a result, there is a growing demand for high-quality packaging to protect these products from damage and keep them looking their best. One of the most popular methods for packaging beauty products is hot stamping.

Hot stamping is a process that uses heat and pressure to apply a design or logo to the surface of a product. This method is often used on cosmetic bottles and jars, providing a durable, long-lasting finish that can resist wear and tear.

Hot stamping can also create a wide range of designs, including complex patterns and images. As a result, it is an ideal way to add style and elegance to any cosmetic product.

Feature

◇It can create a glossy and shiny finish, making your products look more attractive and professional.

◇It can also help to protect your products from UV damage and other environmental factors.

◇Hot stamping is versatile, and you can use it to create all sorts of different designs, logos, and images on your packaging.

◇Hot stamping is a printing technique that uses heat to transfer an image onto a substrate.

◇Hot stamping is an ideal printing method for skin-care packaging because it produces a high-quality, durable image that can withstand the rigors of shipping and handling.

What is the Paint Color?

Knowing the paint color for skin care inner packaging technology is essential. Cosmetic, skin-care, and beauty and wellness industries are growing rapidly, and one way to stand out is to use unique packaging.

Paint color is the best way to add creativity to your product. Whether you’re looking for a subtle change or a complete overhaul, inner packaging is a great way to make your product stand out.

It’s now possible to get custom colors that are specifically formulated for skin-care packaging. This means that you can match your products precisely to your target audience. If you’re looking for an attention-grabbing way to promote your product, consider using inner packaging with a paint color that reflects your brand identity.

Feature

◇Paint color can help to create a luxe look for your products.

◇It can also protect your products from UV light and other environmental factors.

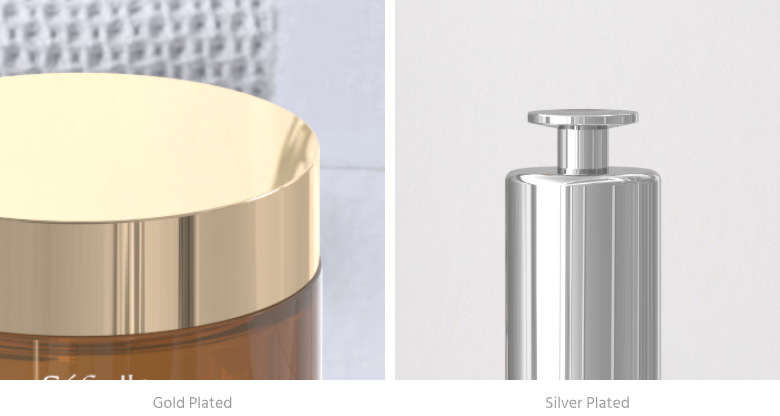

What is electroplating?

In today’s market, there is an ever-growing demand for more innovative and unique packaging solutions that can help to set products apart from the competition. One such solution is electroplating.

Electroplating is a process in which a thin layer of metal is applied to the surface of another material. This process can be used to create a variety of different effects, from a polished finish to a colorful and vibrant design.

When it comes to skin-care packaging, electroplating can be used to create a luxurious and stylish look that is sure to turn heads. Thanks to its ability to add an extra level of charisma, electroplating has become one of the most popular trends in cosmetic packaging. If you’re looking for a way to make your product stand out, electroplating just might be the answer.

Feature

◇A smooth, glossy finish enhances the look of cosmetic products.

◇Excellent durability that can withstand repeated use.

◇Non-toxic materials that are safe for use with cosmetic products.

◇A wide range of colors and finishes can be customized to match the cosmetic product or brand.

What is the frosted?

If you’re a cosmetic or skin-care product Junkie, you’ve probably seen or heard of the term “frosted” in relation to packaging. But what exactly is it, and why is it so important for your products?

Frosted packaging is a type of inner packaging technology that helps to protect your product from damage and keep it fresh for longer. Here’s a closer look at how it works and why it’s so important for healthy skin:

Frosted packaging essentially creates a barrier between your product and the outside world. This helps to protect your product from oxygen, light, and other environmental elements that can cause damage. It also helps to keep your product free from contamination.

This packaging also helps maintain the quality of your product by keeping the active ingredients fresh and effective for longer. When you choose the right frosting for your cosmetic or skin-care products, you can help to ensure that they remain potent and effective for months or even years.

So, if you want to ensure that your cosmetic or skin-care products are as fresh and compelling as possible, be sure to choose to package with frosted technology. It could make all the difference in maintaining healthy skin!

Feature

◇It provides an attractive and eye-catching appearance.

◇Frosted for skin care inner packaging helps protect your products from damage while in transit or storage.

What is the water transfer printing?

Water transfer printing is a technique that can be used to make sure you’re getting the right product for your skin’s specific needs. That’s why it’s important to understand how this technology works before you make a purchase.

Water transfer printing involves using a stencil to apply ink to the inner surface of a packaging container. The ink is then transferred to the outside of the container, creating a design that can be customized to meet your needs.

This technology is often used for skin-care products, as it allows for a wide range of designs and colors. When choosing a water transfer printing technology, make sure you select one with experience in working with skin care products. This will ensure that you’re getting the best possible results for your specific needs.

Feature

◇Water transfer printing creates a smooth, flawless finish on your skin-care packaging.

◇Water transfer printing is a quick and easy way to get your desired design on your packaging.

◇This type of printing is also cost-effective, so you can get the look you want without breaking the bank.

◇Water transfer printing is durable and long-lasting, so your packaging will look great for years to come.

Wrap Up

It is important to consider the surface technics of skin care products when it comes to their inner packaging. This will ensure that the products are able to maintain their quality and efficacy. This blog post will give you the best information about the surface technics that can use inner product packaging.