The production process of skin care products includes multiple steps, from the procurement of raw materials to the packaging of finished products. The following is a general overview of a typical manufacturing process for skin care products:

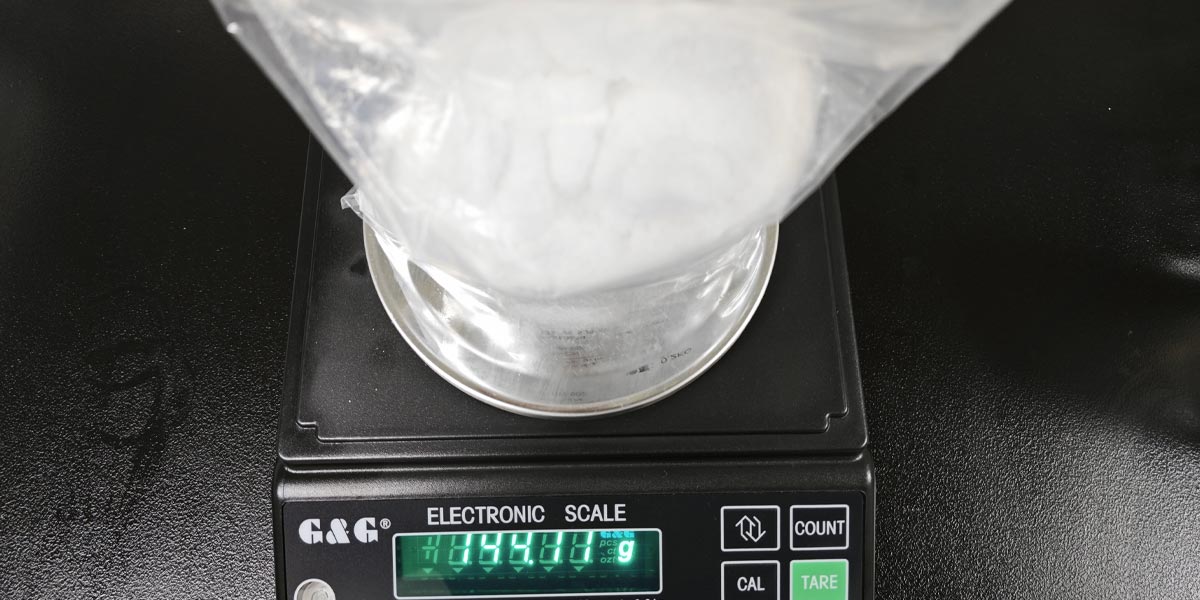

Raw Material Weighing

Weighing skin care products is a critical step in the production process, ensuring that various ingredients are added to the product in the correct proportion. The following is the general process of weighing raw materials for skin care products:

Determine the formula: first, determine the type and proportion of raw materials to be used according to the formula and ratio of the product. The formulation is formulated according to product design requirements and efficacy goals, which includes active ingredients, base oils, emulsifiers, preservatives, fragrances, etc.

Prepare ingredients: Prepare the required ingredients and place them in appropriate containers or volumetric flasks. Ensure that the quality of raw materials meets the requirements and follow relevant safety and hygiene regulations.

Weighing raw materials: Use accurate weighing equipment to weigh raw materials one by one according to the formula requirements. During the weighing process, it is necessary to pay attention to accurately read and record the weight of each raw material, and weigh in strict accordance with the formula ratio.

Control weighing error: When weighing raw materials, pay attention to controlling weighing error. This can be achieved by using accurate weighing equipment, avoiding cross-contamination and giving accurate readings. Additionally, commonly used ingredients can be pre-weighed and packaged to reduce weighing steps in each production run.

Recording and traceability: For each production batch, relevant information such as the weighing amount and batch number of raw materials need to be recorded. This facilitates product traceability and quality control, with subsequent analysis and adjustments if required.

Cleaning and disinfection: After weighing raw materials, the weighing equipment and containers used should be cleaned and disinfected in time to avoid cross-contamination and affect the production of the next batch.

Raw material weighing is a precise job in the production of skin care products, which is crucial to ensure the stability, efficacy and safety of products. Therefore, it is necessary to use accurate weighing equipment, follow the formula ratio and quality control requirements, and carry out strict records and traceability.

Raw Material Inspection

The raw material inspection of skin care products is an important link to ensure product safety and quality. The following are some common skin care product raw material inspection methods and steps:

Physical property inspection: inspect the physical properties of raw materials, including appearance, color, texture, PH value, etc. These tests can be carried out by visual observation, colorimetry, pH meter and other tools.

Chemical composition analysis: analyze the chemical composition of raw materials to determine their composition content and purity. Common analytical methods include chromatography, mass spectrometry, spectroscopy, etc. These methods can help determine whether a raw material complies with relevant safety standards and regulatory requirements.

Microbial testing: Microbial contamination in raw materials is an important consideration for the safety of skin care products. Through microbiological inspection, it is possible to detect whether there are bacteria, fungi, yeast and other microorganisms in the raw materials. Commonly used inspection methods include total colony count, pathogenic bacteria detection, etc.

Residual Solvent Inspection: Certain raw materials may contain residual solvents or hazardous substances. Product safety can be ensured by detecting residual solvents in raw materials. Common inspection methods include gas chromatography, liquid chromatography, etc.

Safety assessment: conduct safety assessment on raw materials, evaluate their skin irritation, allergies and toxicity, etc. Safety assessments are usually conducted through in vitro tests and clinical evaluations.

It is worth noting that raw material inspection is usually carried out by professional laboratories or institutions with relevant equipment and expertise. For skin care product manufacturers, cooperating with reliable suppliers and requiring relevant raw material quality inspection reports are important measures to ensure the quality and safety of raw materials.

Raw Material Mixing

The raw material mixing of skin care products is to mix different raw materials together according to a certain formula and ratio to make the final skin care products. The following are the general raw material mixing steps:

Prepare raw materials: First, you need to prepare the required raw materials for skin care products, including basic ingredients (such as water, oil), active ingredients (such as vitamins, antioxidants), stabilizers, emulsifiers, preservatives, etc. These ingredients are prepared and weighed according to product formulation requirements.

Weighing and proportioning: Accurately weigh the required raw materials according to the ratio of each raw material in the product formula. This can be achieved through dedicated weighing instruments and accurate proportioning formulas. Ensuring accurate proportioning according to formula requirements is the key to product quality.

Mixing and stirring: gradually add the weighed raw materials into the mixing container, and stir and mix. The method of mixing and stirring can choose appropriate equipment according to the nature of the raw materials and the requirements of the formula, such as agitator, stirring rod or stirring tank. The purpose of stirring is to ensure that the ingredients are thoroughly mixed to form a homogeneous mixture.

Temperature Control: It may be necessary to control the temperature during the mixing process of some raw materials. For example, during emulsification, heating or cooling may be required to achieve optimal emulsification. Ensuring proper temperature during raw material mixing ensures product stability and quality.

Safety measures: In the process of mixing raw materials, safety measures need to be paid attention to. Some raw materials may be irritating or harmful, and it is necessary to follow the correct operating procedures and use personal protective equipment, such as gloves, glasses, etc., to ensure the safety of the operator.

Finally, after the preparation, weighing, mixing and processing of raw materials, after the raw materials of skin care products are mixed, subsequent processing, canning, packaging and other steps can be carried out to finally make finished skin care products. It is worth noting that relevant regulations and quality standards must be followed in the production process of skin care products to ensure product safety and compliance.

Raw Material Emulsification

In the skin care manufacturing process, emulsification is an important step used to mix oil-based and water-based ingredients together to form a stable milky or gel-like product. The following is the general process of emulsification of raw materials for skin care products:

Prepare the oil phase and water phase: First, prepare the two basic ingredients of the oil phase and the water phase. The oil phase is usually composed of oils, fatty acids, emulsifiers and other auxiliary ingredients, and the water phase is usually composed of water, active ingredients, stabilizers and other water-soluble ingredients.

Heating the oil phase and water phase: Heat the oil phase and water phase to appropriate temperature respectively. Heating helps change the viscosity of the ingredients, facilitates the mixing process, and improves emulsification.

Adding the emulsifier: Gradually add the emulsifier to the heated water phase. The emulsifier forms a molecular film on the oil-water interface, which helps to mix and stabilize the oil-water phase.

Mixing and emulsification: Slowly pour the heated water phase into the heated oil phase with mixing and stirring. Adequate mixing and emulsification is usually achieved using agitators or emulsifying equipment.

Cooling and Stabilization: After the mixing and emulsifying process, the emulsified product is cooled to room temperature. During cooling, the product gradually stabilizes, developing a creamy or gel-like texture.

Adding other ingredients: According to the product formula, other active ingredients, fragrances, preservatives, etc. can be added on the emulsified basis.

The process of emulsification requires proper control of temperature, emulsifier ratio and stirring time to ensure the quality and stability of the final product. Emulsification can form fine emulsion or gel particles, so that oil and water can disperse and keep stable, so as to achieve the uniform texture and use experience of skin care products.

Semi-finished Product Inspection

Semi-finished product inspection of skin care products is an important step to ensure product quality and safety. The following are some common semi-finished product inspection items:

Raw material testing: testing of raw materials used in the manufacture of skin care products to ensure that they meet quality standards and regulatory requirements. This includes testing raw materials for purity, stability, safety, and other relevant characteristics.

Mixing ratio detection: accurate mixing ratio detection of different raw materials according to the formula to ensure the accuracy and consistency of the product formula.

PH value detection: Detect the pH value of skin care products to ensure that it is within the appropriate range. The control of PH value is very important for maintaining the acid-base balance of the skin and protecting the health of the skin.

Stability testing: Long-term stability testing is used to evaluate product stability and durability. This includes testing with exposure to different temperature, humidity and light conditions to simulate the environment the product is likely to encounter in actual use.

Microbiological testing: Microbiological testing is performed on skin care products to ensure that the products do not contain harmful bacteria, molds or other microorganisms. This includes total colony counts, detection of pathogenic bacteria and effectiveness of preservatives, etc.

Physical property testing: test the physical properties of skin care products, such as viscosity, fluidity, stability and particle size, etc. This helps ensure that the product looks and works as expected.

Safety assessment: through safety assessment to evaluate the safety of the product on the skin and human body. This includes skin irritation testing, eye irritation testing and allergy testing etc.

The above are some common test items for semi-finished skin care products. The specific test content and methods will vary according to product types and requirements. These tests help ensure the quality and safety of skin care products to provide consumers with safe and effective products.

Microbial Detection

In the production of skin care products, microbiological testing is an important quality control step to ensure the microbiological safety and stability of products. Microbiological testing usually includes the following aspects:

Total Colony Count: This is a common microbial testing method used to determine the overall microbial count in skin care products. It works by preparing a sample into an appropriate dilution series, inoculating it on a rich medium, and counting the number of colonies grown. TPC testing is able to assess whether skin care products are contaminated by microorganisms such as bacteria, yeast and mold.

Specific microorganism detection: In addition to the total colony count, specific microorganism detection can also be carried out, such as E. coli, Staphylococcus aureus, yeast and mold, etc. These microorganisms may be pathogenic and pose a potential threat to human health. Through specific microbial testing, it is possible to ensure that skin care products are not contaminated by these harmful microorganisms during the production process.

Preservative Efficacy Testing: Preservatives are often added to skin care products to prevent microbial contamination and product spoilage. Preservative efficacy testing evaluates the effectiveness of preservatives in skin care products to ensure that they are effective in inhibiting the growth of microorganisms for a specified period of time.

Stability test: Stability test is a test for the entire life cycle of skin care products to determine the microbial stability of the product under different environmental conditions. These tests usually include consideration of factors such as temperature, humidity and time to simulate the actual use conditions of the product.

The results of microbiological testing can be used to assess the microbiological quality of skin care products and ensure that the products comply with relevant regulations and standards. Through reasonable microbial control measures and monitoring, the safety, stability and quality of skin care products can be guaranteed, thereby protecting the health of users.

Canning & Packaging

Canned skin care products usually refer to putting skin care products in canned containers for convenient use and storage. The following are the general steps for canning skin care products:

Prepare canning containers: choose appropriate canning containers, which can be plastic jars, glass jars or metal cans, etc., and choose the appropriate material and size according to the nature and requirements of the product.

To Fill Product: Pour skincare product into prepared jar containers. This may involve the use of automatic or semi-automatic filling equipment to ensure that the product is properly filled into the filling container.

Sealed canning container: Once the product is filled into the canning container, it needs to be sealed. This can be done by screw caps, crimps or parafilm. The purpose of sealing is to ensure the shelf life of the product and prevent contamination.

Labeling and Packaging: Add labels and packaging to jar containers to provide product information and brand identity. The label usually includes information such as the product name, ingredients, directions for use, shelf life, etc. Inclusions may include placing the canned container in a box, bag, or wrapping to protect the product.

Quality control and inspection: Quality control and inspection are carried out during the canning process to ensure that the products meet the standards and requirements. This can include checking the tightness of containers, the accuracy of labels and the quality of product appearance, among other things.

Finished Product Inspection

Finished product testing of skin care products is the process of quality control and safety testing of the final product after the product is manufactured. These tests are designed to ensure that products comply with relevant regulations and standards, and meet the needs and expectations of consumers. The following are some common testing items for finished skin care products:

Physical property detection: including detection of appearance, color, smell, texture, PH value, etc. These tests can help determine the cosmetic quality and consistency of the product.

Chemical ingredient testing: analysis and testing of chemical ingredients in skin care products to ensure compliance with regulations and standards. This can include quantitative and qualitative analysis of active ingredients, preservatives, sunscreens, fragrances, colorants.

Microbiological testing: skin care products should meet the requirements of microbiological safety, so microbiological testing is very important. Common testing items include total colony count, mold and yeast testing, and pathogenic bacteria (such as E. coli, Staphylococcus aureus, etc.).

Stability and shelf life testing: Skin care products should have appropriate stability and shelf life to ensure that the product maintains its quality and performance during its expiry date. These tests can include stability assessments under temperature and light conditions, microbiological stability tests, etc.

Skin irritation and allergy testing: Skin care products should be tested for skin irritation and allergy to evaluate their safety on the skin. These tests can use human volunteers for skin irritation tests, sensitization tests, etc.

Safety Assessment: Conduct a comprehensive product safety assessment, taking into account the toxicological data of the ingredients in the product, the mode of use and the expected exposure, to ensure the safety of the product for the user.

These tests are usually performed by specialized laboratories or in-house quality control teams to ensure the quality and safety of skincare products. The standards and requirements of these tests may vary by region, country or product type, but the purpose is to ensure that products meet quality standards and regulatory requirements, and to ensure consumer safety and satisfaction.

Storage And Distribution

The storage and distribution of skin care products is an important part of ensuring the quality and safety of products in circulation. Here are some common practices for storing and dispensing skin care products:

Storage conditions: The storage conditions of skin care products are crucial to the quality of the products. Generally speaking, skin care products should be stored in a dry, cool, dark and well-ventilated place. Avoid exposure to high temperature, high humidity and direct sunlight to avoid affecting the stability and effect of the product.

Temperature Control: Certain skin care products may be temperature sensitive and therefore require proper temperature control during storage and distribution. Especially for products containing active ingredients, natural extracts or microbial protection agents, it is necessary to ensure that they are stored and transported within the recommended temperature range to maintain their stability and activity.

Packaging and Sealing: Proper packaging and sealing are key to ensuring that skin care products maintain their quality during storage and distribution. Canned or bottled products should have good airtightness to prevent contamination and loss of volatile components. The outer packaging material should be able to protect the product from the external environment, such as light, moisture and pollution.

Transportation and distribution: During the distribution of skin care products, it is necessary to choose the appropriate transportation method and suitable packaging materials to ensure that the products will not be damaged or the quality will be affected during transportation. SaveMaintain proper temperature control and protective measures to ensure that the product reaches its purpose safely.

These practices can help ensure that skin care products are of good quality and safe during storage and distribution. Manufacturers, suppliers and retailers should follow the relevant standards and regulations and take appropriate measures.